The following step can be used as reference in design power cable for electrical system.

The following step can be used as reference in design power cable for electrical system.

1. Data Gathering

Typically, we will need the following data:

a. Load Details

The characteristic of the load that cable will supply:

- Load type: motor or feeder

- Three phase, single phase or DC system

- Voltage level of the system

- Rated power of the load (kW)

- Starting current type if load type is motor

- Distance / length of the cable.

b. Cable Construction

The characteristic of cable physical construction, which include:

- Conductor material: normally copper or aluminum

- Conductor shape: i.e. circular or shaped

- Conductor type: i.e. stranded or solid

- Conductor surface coating: i.e. plain (no coating), tinned, silver or nickel

- Insulation type: PVC (PolyVinyl Chloride), XLPE (Cross Linked PolyEthane) or EPR (Ethylene Propylene Rubber)

- Number of core, single core or multi core: i.e. 2C, 3C or 4C.

c. Installation Condition (de-rating factor)

How the cable will installed, which include:

- Above ground or under ground

- Installation arrangement: for underground cable, it is direct buried or install in conduit. For above ground cable, it is install on cable tray / ladder, against a wall, in air, etc.

- Ambient temperature for above ground installation and soil temperature for underground installation.

- Cable bunching: i.e. the number of cable that are bunched together

- Cable spacing: i.e. whether cable installed touching or spaced

- Soil thermal resistivity for underground installation

- Depth of laying for underground installation

- For single core and three phase cable, are the cable installed in trefoil or laid flat?

2. Cable Selection Based On Current Rating

After all data collected, we should calculate the load current (or nominal current) and multiply with all de-rating factor above and then calculate circuit breaker current. This circuit breaker current will be used as basis current to choose the cable size. The ampacity (Ampere Capacity) of the each size of the cable normally refer to manufacturer standard, each manufacturer has different ampacity even for the same size but not significant.

If ≤ Ip ≤ Ic

If = Full load current (A)

Ip = Protective device rating (A)

Ic = Installed Current Rating (A)

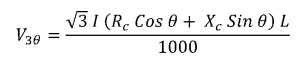

3. Voltage Drop

Voltage drop of the cable will depend on the followings:

- Current flow through the cable – the higher the current flow, the higher the voltage drop

- Impedance of the conductor – the larger the impedance, the larger the voltage drop

- Length of the cable – the longer cable will increase the voltage drop

V3ɸ = Voltage Drop 3 phase (V)

Rc = Resistance of the cable (Ὠ/km)

Xc = Reactance of the cable (Ω/km)

I = Nominal Current (A)

L = Length of the cable (m)

Maximum Voltage Drop

For normal condition, allowable voltage drop normally up to 5%. For starting condition, allowable voltage drop normally 15%.

4. Short Circuit Temperature Rise

Short circuit current also to be consider in design power cable. During short circuit condition, surge of current flow will caused temperature rise on the cable. So, we shall consider the short circuit condition. The following formula calculate the minimum size of conductor depend on short circuit current and the fault duration.

A = Minimum cross-sectional area of the cable (mm2)

i = Short circuit current (A)

t = short circuit duration (s)

k = short circuit temperature rise constant

5. Select the cable based on the highest of the sized calculated on in step 2-4.

Source:

- Electrical Design Guide According to IEC Standard: Open Electrical

Applicable Standard:

- IEC 60364-5-54 (2009)

- NFPA 70 (2011)

- BS 7671 (2008)

- AS/NZS 3008.1 (2009)